Hybrid Tiny Home

JC Foreman / Access Tiny Homes

Solid construction, built to last and for on the go.

Ready (In Stock)

$54,900

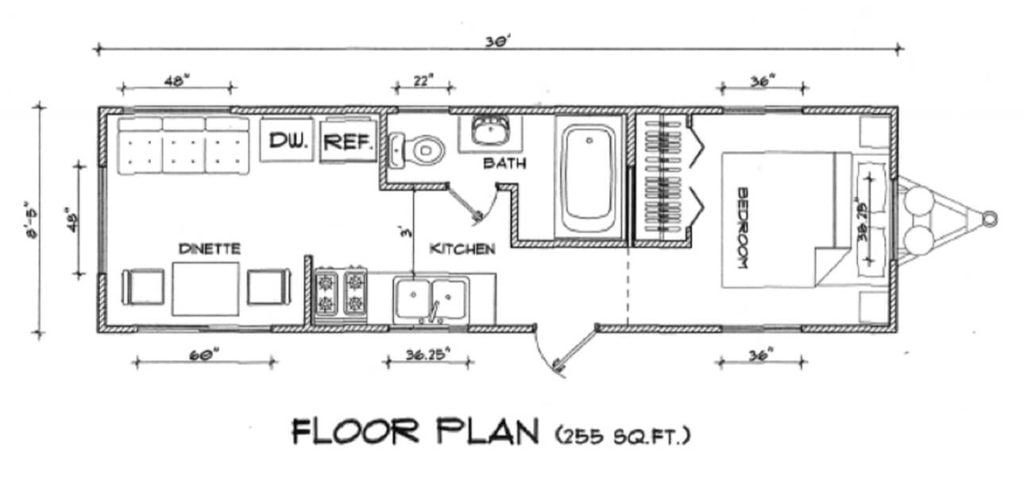

4 residents / 1 bedroom

$13,725 / resident

Long-Term/Permanent (15+ years)

| 45 days offsite | 1 days onsite |

| Design Advantages | Access Tiny Homes (ATH) are built with solid construction utilizing better, higher quality materials. ATH products are insulated like a traditional home, and have roofing and siding that meet California Fire Codes. ATH quality roofing and siding carry a 40 year manufacturer warranty. |

| Manufacturer Identified | Yes |

| Used for shelter in the U.S.? | Yes |

| Prior use examples | ATH manufacturing partner has been at the forefront of many US disaster needs for shelter. |

| Prior use comments | ATH has several models available for emergency housing, supportive housing, transitional housing, as well as consumer solutions. |

| Building experience comments | ATH has over 90+ years in the RV and manufactured homes industry. Our base units are built to support various price points and amenities, carrying a 40 year warranty on roof and siding materials. We are able to build to scale. Currently we can build 2,000+ units per year, and have additional manufacturing space that can come on line quickly. |

| Intended use cases | The intended use of our ATH units are for emergency shelter to family shelter. |

| R-value (insulation) | 21-30 |

| Risk Category | |

| Roof Load (PSF) | 40 |

| Indoor Clearance Height (ft) | 10 |

| Waterproof? | Yes |

| Professional Engineer Stamp? | |

| Conforms to ICC’s Temporary Structure and Uses Code | |

| Other Structural / Safety Comments | RVIA certified |

| Sustainability / Green Building Certifications? | |

| Materials Used / Made of: | Wood, metal, vinyl windows, fiberglass shower, Quartz countertops, stainless steel sinks, porcelain toilet, LP Smart Side Lap Siding, R 28 insulation, Darko floor wrap. |

| Disassembly / Assembly Comments: | |

| Ideal Mounting Surfaces | Soil (Dirt/Grass), Asphalt / Parking Lot, Other |

| Anchoring Process |

| Design Advantages | Access Tiny Homes (ATH) are built with solid construction utilizing better, higher quality materials. ATH products are insulated like a traditional home, and have roofing and siding that meet California Fire Codes. ATH quality roofing and siding carry a 40 year manufacturer warranty. |

| Manufacturer Identified | Yes |

| Used for shelter in the U.S.? | Yes |

| Prior use examples | ATH manufacturing partner has been at the forefront of many US disaster needs for shelter. |

| Prior use comments | ATH has several models available for emergency housing, supportive housing, transitional housing, as well as consumer solutions. |

| Building experience comments | ATH has over 90+ years in the RV and manufactured homes industry. Our base units are built to support various price points and amenities, carrying a 40 year warranty on roof and siding materials. We are able to build to scale. Currently we can build 2,000+ units per year, and have additional manufacturing space that can come on line quickly. |

| Intended use cases | The intended use of our ATH units are for emergency shelter to family shelter. |

| R-value (insulation) | 21-30 |

| Risk Category | |

| Roof Load (PSF) | 40 |

| Indoor Clearance Height (ft) | 10 |

| Waterproof? | Yes |

| Professional Engineer Stamp? | |

| Conforms to ICC’s Temporary Structure and Uses Code | |

| Other Structural / Safety Comments | RVIA certified |

| Sustainability / Green Building Certifications? | |

| Materials Used / Made of: | Wood, metal, vinyl windows, fiberglass shower, Quartz countertops, stainless steel sinks, porcelain toilet, LP Smart Side Lap Siding, R 28 insulation, Darko floor wrap. |

| Disassembly / Assembly Comments: | |

| Ideal Mounting Surfaces | Soil (Dirt/Grass), Asphalt / Parking Lot, Other |

| Anchoring Process |

| Item | Cost ($) | Notes |

| Materials | $54,900 | Total cost delivered 27450 |

| Labor | $0 | |

| Delivery | $0 | |

| $0 | ||

| $0 | ||

| $0 | ||

| Budget Total | $54,900 | |

| Total Per Bed | $13,725 | |

| Total Per Unit | $54,900 | |

| Add-on Items | Stairs and decking if applicable. Price dependent on quantity orders. | |

| Check all items that are not included in your quote (i.e. would need to be quoted by outside party) | ||

| List outside vendors needed to execute (including any architects and engineers) | None | |

| Possible Delivery Method(s) | ||

| Design (days) | 0 |

| Production (days) | 45 |

| Site Prep (days) | 0 |

| Delivery (days) | 0 |

| Total (days) | 45 |

| Amount in Inventory (#) | 2 |

| Production Capacity | 165 per month |

| Production Location | Nappanee, Indiana, USA |

NEXT

NEXT