Ablenook 001

Ablenook

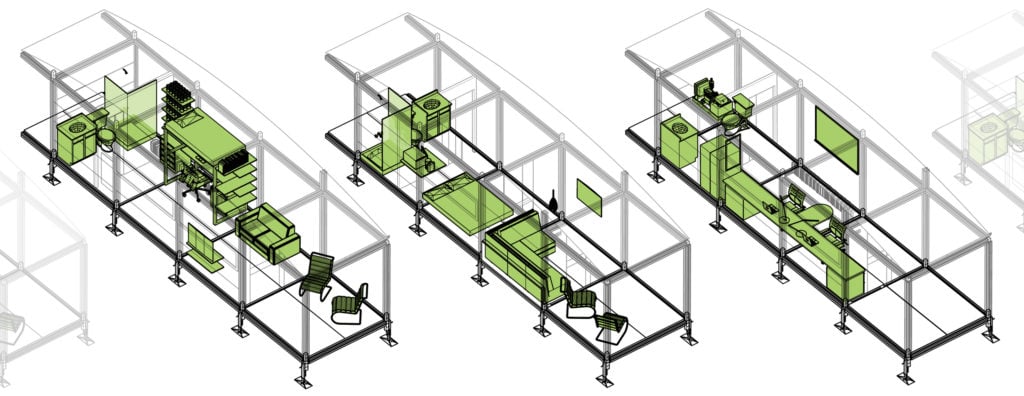

Assembles without tools, resists hurricanes, infinitely expandable, and can go anywhere without heavy equipment like cranes.

Built Prototype Only

$75,000

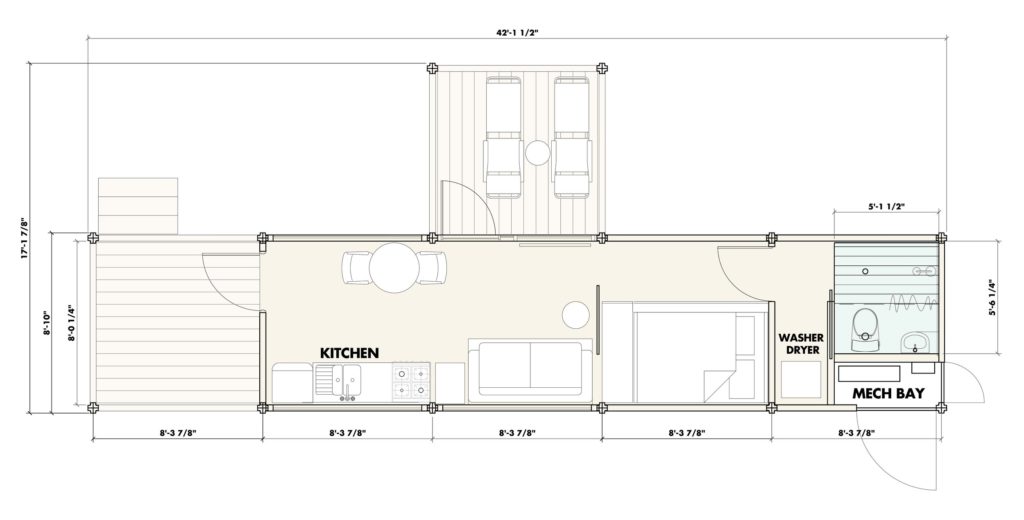

2 residents / 1 bedroom

$37,500 / resident

Long-Term/Permanent (15+ years)

| 4 days offsite | 1 days onsite |

AbleNook is a new kind of home that assembles without tools, is infinitely expandable, resists hurricanes and can go anywhere without heavy equipment like cranes.

- Quoted Total Cost: $75,000

- Planned Occupancy (1 person/bed): 2 beds

- Estimated Cost Per Bed: $37,500

- Quote’s Total Interior Square Footage: 270 sqft

- Quote Includes # Units: 1 unit

- Used for Shelter Before: Not used as shelter yet

- Readiness: Built Prototype Only

- In Stock / Ready to Ship Today: No

- Manufacturer Identified and Available: N/A

- Setup Speed: 6 days

- Setup Difficulty: Moderate (prefab assembly)

- % Built Onsite: 50% – Some Prefab Parts Assembled On-Site/Flat Pack

- Portability: Portable (after major disassembly)

- Intended Use of Shelter: Long Term/Permanent (15+ years)

| Design Advantages | + Can be deployed on uneven terrain+ Units can be assembled by unskilled individuals, without power tools

+ Integrated electrical + Can be expanded for larger space requirements + Thermally insulated + Units can be used for residential, military, home office, and school + Thermodynamically based upon bungalow typology = passive cooling effect + Can be re-used = long term savings + Units are shipped flat packed + More units can be delivered per truck load to disaster areas |

| Manufacturer Identified | No |

| Used for shelter in the U.S.? | No |

| Prior use examples | Built prototype in factory only |

| Prior use comments | |

| Building experience comments | |

| Intended use cases | |

| R-value (insulation) | 31-40 |

| Risk Category | |

| Roof Load (PSF) | |

| Indoor Clearance Height (ft) | 7 |

| Waterproof? | Yes |

| Professional Engineer Stamp? | |

| Conforms to ICC’s Temporary Structure and Uses Code | |

| Other Structural / Safety Comments | |

| Sustainability / Green Building Certifications? | |

| Materials Used / Made of: | Flat packed, site assembled kit that consists of a lightweight aluminum structural frame that slides/snaps together with SIPs (structural insulated panels) for floors, walls and ceilings. |

| Disassembly / Assembly Comments: | Assembly and disassembly are the same process but in reverse for the AbleNook. There are no nails or glue to be stripped when disassembly simply pull the levers or latches and the structure will come apart piece by piece |

| Ideal Mounting Surfaces | Soil (Dirt/Grass), Asphalt / Parking Lot, Other |

| Anchoring Process | Depending on the location this can change. Jay bolts or simple anchors will work with the AbleNook system |

| Item | Cost ($) | Notes |

| Materials | $75,000 | |

| Labor | $10,000 | |

| Delivery | $2,000 | |

| $ | ||

| $ | ||

| $ | ||

| Budget Total | $87,000 | |

| Total Per Bed | $43,500 | |

| Total Per Unit | $87,000 | |

| Add-on Items | ||

| Check all items that are not included in your quote (i.e. would need to be quoted by outside party) | Foundation work, Delivery Charge, Other | |

| List outside vendors needed to execute (including any architects and engineers) | Hookup connections with city or local governments are not included. any work on the terrain will need to be executed prior to deployment. | |

| Possible Delivery Method(s) | Flat pack module, Regular-sized trailer, Over-sized trailer | |

| Design (days) | 2 |

| Production (days) | |

| Site Prep (days) | |

| Delivery (days) | 2 |

| Total (days) | 6 |

| Amount in Inventory (#) | 0 |

| Production Capacity | 30 |

| Production Location | Tampa, Florida, USA |

NEXT

NEXT