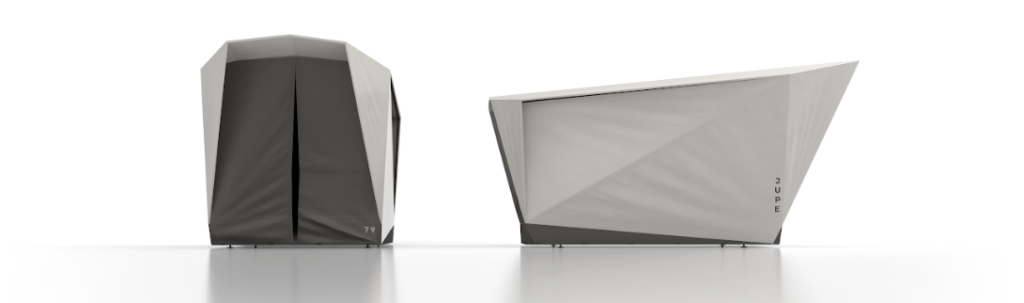

Jupe Single

Jupe

Portable, stylish, pop-up shelter for rentals, emergencies, and adventures...

Ready (In Stock)

$6,000

2 residents / 1 bedroom

$ / resident

Medium Term (1-10 years)

| 28 days offsite | 2 days onsite |

Jupe is reimagining structures from the ground up. What the Rivian chassis does for myriad electric vehicles (i.e. Ford, Amazon Delivery, etc), Jupe’s chassis is doing for all types of housing and the built environment. The Jupe is a flat packed transportable platform that contains the guts of a structure’s use case. Jupe can act as the foundation interface for medical units in a pandemic, backyard homes (ADUs) in San Jose, to transitional disaster relief housing in Puerto Rico. Jupe platforms come ‘pre-charged’ upon arrival (24 to a trailer) with a week’s worth of power and water.

- Quoted Total Cost: Lease Only ($500/Month, $6,000/year)

- Planned Occupancy (1 person/bed): 1 bed

- Estimated Cost Per Bed: Lease Only ($500/Month, $6,000/year)

- Quote’s Total Interior Square Footage: 111 sqft

- Quote Includes # Units: 1 unit

- Used for Shelter Before: Yes, examples in the U.S.

- Readiness: Ready to Ship

- In Stock / Ready to Ship Today: Yes

- Manufacturer Identified and Available: Yes, Jupes built in their factory in Los Angeles, CA

- Setup Speed: 30-60 days

- Setup Difficulty: Low skill (RV, tent)

- % Built Onsite: <10% – Arrives Ready, Almost All Built/Assembled Off-Site

- Portability: Semi-Mobile (detachable, minor disassembly)

- Intended Use of Shelter: Medium Term (1-10 years) years

| Used for shelter before? | Yes |

| Used for shelter in the U.S.? | Yes |

| If so, list examples | Current uses are product testing – design team is staying in the unit themselves. |

| Prior use comments | |

| Building experience comments | |

| Intended use cases | Backyard and garage units, disaster relief, homeless housing, medical. |

| R-value (insulation) | |

| Risk Category | |

| Roof Load (PSF) | 0 |

| Indoor Clearance Height (ft) | 10 |

| Waterproof? | Yes |

| Professional Engineer Stamp? | |

| Conforms to ICC’s Temporary Structure and Uses Code | |

| Other Structural / Safety Comments | |

| Sustainability / Green Building Certifications? | |

| Materials Used / Made of: | Plywood, lumber, aluminum, various tent materials. |

| Disassembly / Assembly Comments: | |

| Ideal Mounting Surfaces | |

| Anchoring Process |

| Item | Cost ($) | Notes |

| Materials | $ | |

| Labor | $ | |

| Delivery | $ | |

| $ | ||

| $ | ||

| $ | ||

| Budget Total | $15,000 | |

| Total Per Bed | $7,500 | |

| Total Per Unit | $15,000 | |

| Add-on Items | ||

| Check all items that are not included in your quote (i.e. would need to be quoted by outside party) | ||

| List outside vendors needed to execute (including any architects and engineers) | ||

| Possible Delivery Method(s) | ||

NEXT

NEXT