Tension Fabric Structure

Fortress Fabric Structures

Tensioned custom fabric structures offer many advantages over traditional buildings. They can be relocated, erected on any surface, ready in weeks, use natural light, and are easily installed.

Nearly Ready (Prior Use Cases)

$78,000

50 residents / 1 congregate tent

$3,034 / resident

Medium Term (1-10 years)

| 45 days offsite | 45 days onsite |

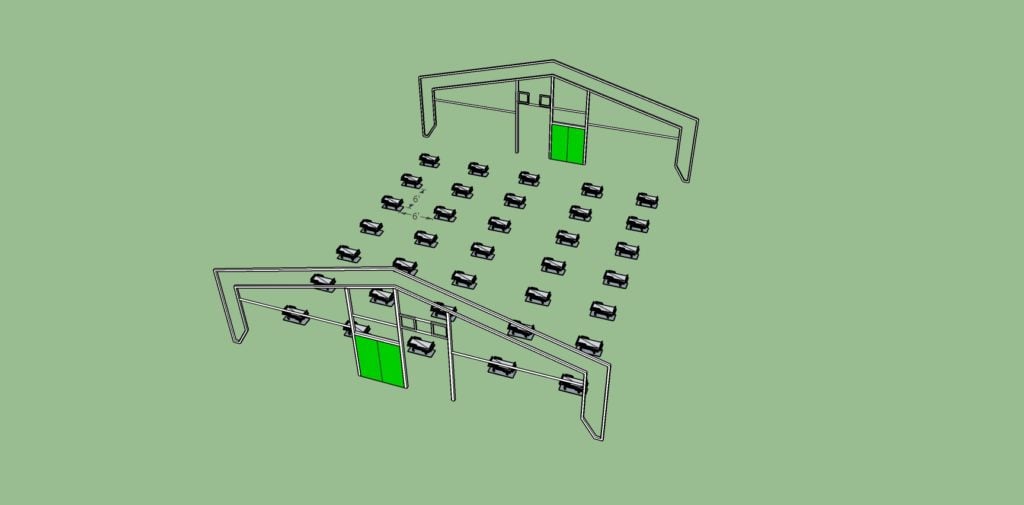

Tension Fabric Structures offer a unique shelter experience and can fulfill any need where weather protection is essential, lead time is critical and site preparation is minimal. Relocatable shelters can be quickly delivered to provide durable space for housing, medical support, storage or any Customer need.

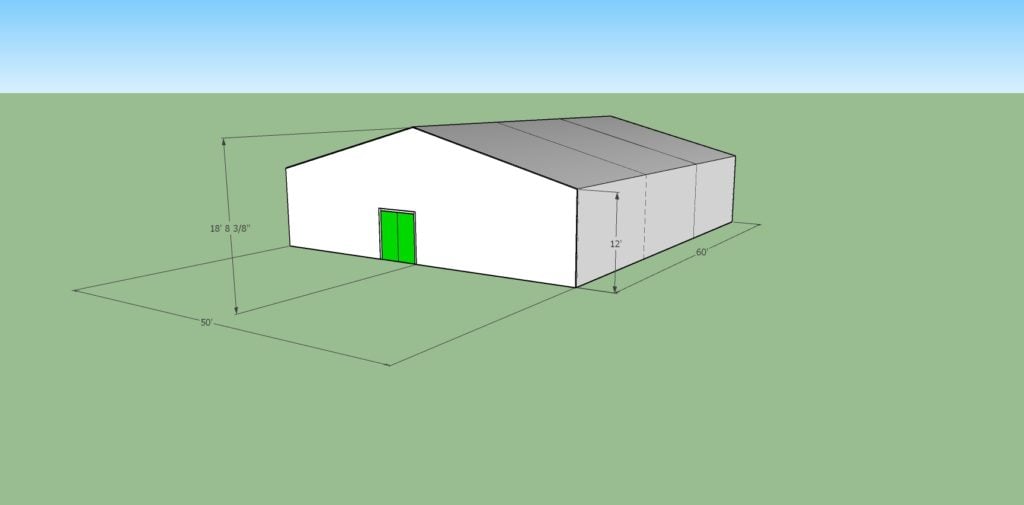

- Quoted Total Cost: $78,000

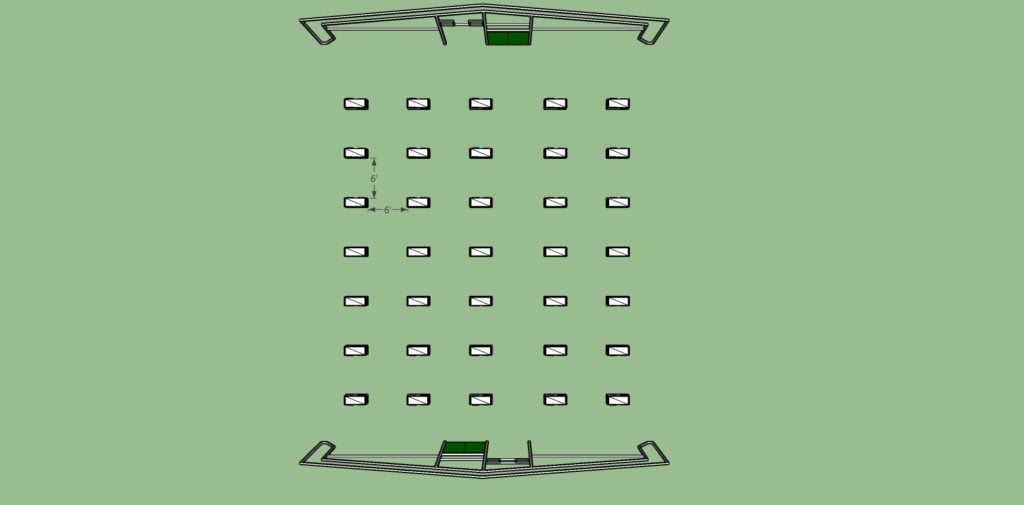

- Quote’s Total Interior Square Footage: 4,000 sqft

- Quote Sleeps # People/Beds: 50 beds

- Quote Includes # Units: 1 units

- In Stock / Ready to Ship Today: No

| Used for shelter before? | Yes |

| Used for shelter in the U.S.? | Yes |

| If so, list examples | Previous projects used as remote oil and gas housing, industrial lunchrooms, a post office, aircraft hangars, warehouses and shade structures. |

| Prior use comments | Shelters are designed to building code standards for each Customer’s location to meet local wind and snow loads. Accessories and specific features to meet Customer need are almost unlimited. |

| Building experience comments | Fortress Fabric Structures’ team has been involved with designing, manufacturing and installing Tension Fabric Structures for many years with structures dating to the early 2000’s in the US and abroad. Previous projects used as remote oil and gas housing, industrial lunchrooms, a post office, aircraft hangars, warehouses and shade structures. |

| Intended use cases | Durable but temporary housing or medical support as reserve hospital ward space. |

| R-value (insulation) | 0-10 |

| Risk Category | II |

| Roof Load (PSF) | 15 |

| Indoor Clearance Height (ft) | 9 |

| Waterproof? | Yes |

| Professional Engineer Stamp? | Typically yes. Shelter can be made to lighter Temporary Structure standards if desired. |

| Conforms to ICC’s Temporary Structure and Uses Code | Exceeds Temporary Category. Meets ASCE7 Risk Category II, for occupied structures. |

| Other Structural/Safety Comments | Typically designed/engineered to meet Risk Category II (standard occupied structure rating) but can be designed to Risk Category III if desired. |

| Sustainability/Green Building Certifications? | Translucent fabric softly filters daylight to create a pleasant environment that reduces or eliminates the need for daytime lighting. Steel is infinitely recyclable. |

| Materials Used/Made of: | Galvanized A500 structural steel tubing, aluminum extrusions and PVC coated architectural fabric with a top finish. |

| Mobile? | Not intended to be moved once set up. |

| Disassembly/Assembly Comments: | Shelters are assembled on site using structural bolts and hardware. Shelters are relocatable but best used for a site where desired service life is one to twenty years. |

| Ideal Mounting Surfaces | Soil (Dirt/Grass), Asphalt / Parking Lot, Other |

| Anchoring Process | Threaded rod anchors to concrete foundation, helical piles, attached to Customer’s frame (e.g. atop shipping containers) |

| Design (days) | 14 |

| Production (days) | 28 |

| Site Prep (days) | 7 |

| Delivery (days) | 3 |

| Total (days) | 52 |

| Amount in Inventory (#) | Made to Customer specifications |

| Production Capacity | |

| Production Location | USA |

NEXT

NEXT